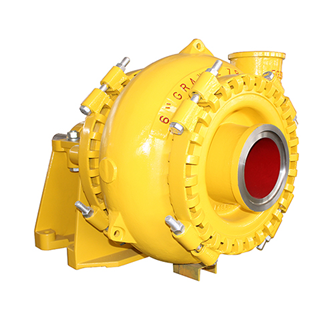

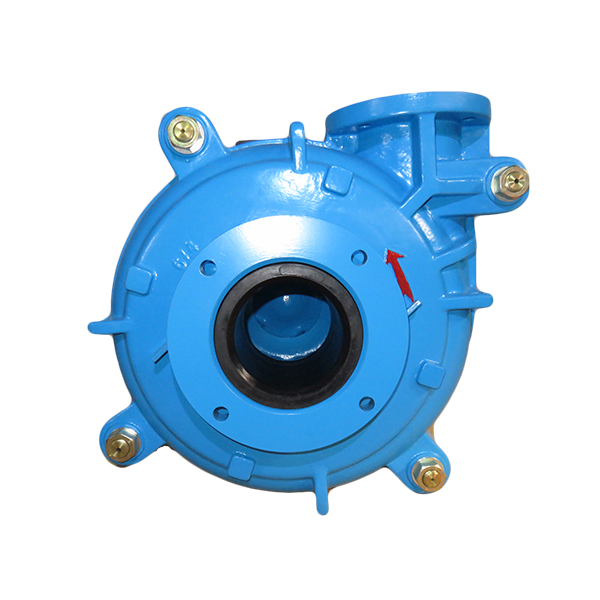

AJH Series: High Head, Heaviest Duty Slurry PumpsAJH series pump were designed to produce high heads per stage at high pressures. Commonlyused for long distance transport lines, the AJH lines can often satisfy application duties with a singlepump where others require multiple pumps.The range is capable of handling medium size particlesand pumping at heads in excess of 90 meters per stage.High Head Slurry Pumps Working RangeDischarge Diameters - 1" to 4" (25mm to 100mm)Flow Rate to 720m3/hHead Range to 118m High Head Slurry Pumps FeaturesIMPELLERS - Various of metal and elastomer interchangeable. Front and rear shrouds have pump out vanes that reduce recirculation and seal contaminationLINERS - Various of metal and elastomer interchangeable. Easily replaceable liners are bolted, not glued to the casing for positive maintenanceTHROATBUSH - Various of metal and elastomer interchangeable. Wear is reduced and maintenance simplified by the use of tapered.EXPELLER SEAL - available with low flow water flush or zero flow (grease lubricated) options to provide exceptional sealing where water introduction to the seal is intolerable or limitedSTUFFING BOX - gland sealing with packing and lantern ringBEARING ASSEMBLY - Bearing assembly is adoptable of cylindrical structure, it is easy to adjust the space between impeller and front liner . Can be removed completely when repaired. Bearing assembly use grease lubricationCASING - Casing halves of cast or ductile iron provides high operating pressure capabilitiesBASE - A single piece base cradles the cartridge type bearing and shaft assembly. An external impeller adjustment mechanism is provided below the bearing housing for easy adjustment of impeller clearanceApplicationsAJH pumps are used to pump high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones and etc. in the industries of metallurgy, mining, coal, power, building material and etc. The temperature of the pumped solid-liquid mixture should be ≤80℃, and the weight concentration should be ≤60.

View More